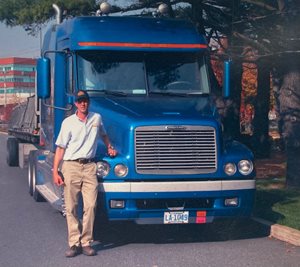

The journey in fuel efficiency continued with my purchase of a 2001 Freightliner Century 70” mid-roof. This truck was purchased from the Charlotte Freightliner dealership and my salesman, Larry Watson, had actually found this truck for me at another dealership in Tennessee. The truck's specifications were as follows: Detroit Series 60 500HP / 1650 FPT, Eaton 10-speed ROADRANGER overdrive manual transmission, Meritor rear axles equipped with 3.55 rear axle ratio, and Michelin lo-pro tires.

Keep in mind that I was still a flatbed carrier. Many people said to me that aerodynamics didn’t matter in hauling open deck freight. I had learned a lot about aerodynamics pulling flatbeds with my previous FLD 120 Freightliner. At this point, one of my major customers was transporting chain link fence. To put it simply, hauling this product is an aerodynamic nightmare. Nearly 50% of my miles were hauling chain link fence. I learned different ways to have the chain link fence loaded on my trailer, which dramatically affected my fuel efficiency. This particular customer for which I hauled chain link fence, had three of their own tractor trailers in which they transported their product to many of the same locations as I did. By paying attention to the details, I was able to average 7.2 mpg while hauling freight in both directions, while their company trucks came back empty and only averaged in the low 5 mpg range.

There was one particular item that I liked to haul with this truck. It was composite decking. Composite decking was a low profile load even though it was heavy. The nice thing was that I was able to average 8+ mpg while hauling this product. My gross combination vehicle weight while hauling composite decking was 79,000+ pounds.

Another primary shipment that was transported by my Freightliner Century, was drywall. The drywall loads had me typically, as I used to put it, “a cup of coffee away from being overweight”. The drywall plant had everything figured out to pretty much put us up against our weight limit. One of the areas in which I was able to greatly increase my efficiency over my competitors while hauling drywall, was in the fact that I pulled a 48' air ride sliding axle trailer vs. their 48' trailers with 10'1 spread axle.

The efficiency was gained in two ways. The first was a closed tandem trailer axle assembly, as it’s easier to pull due to the less scrub exerted on the tire tread. Also, I was able to move my load further forward on the trailer for better aerodynamics. A typical load out of the drywall plant was generally 17 bundles of 48” x 12' material. The drivers pulling spread axles would generally load the product directly in the center of the trailer with 5 bundles in the front, followed by two stacks of 6.

Because of what I’d learned from aerodynamics, I loaded my drywall one foot from the front of the trailer with six bundles in each of the first two positions, followed by the stack of five, which tapered the load into the shape of a rain drop. To have my axle weight legal, it required me to have the trailer axles slid forward to the minimum 36' bridge law position. This enabled me to attain fuel mileage in the high 7 mpg range. Another benefit of pulling the closed tandem slider assembly was greater maneuverability, and a tire replacement life cycle as high as 425,000 miles.

I almost forgot another change that I made to this truck shortly after I purchased it; I quickly discovered that I wasn't getting to my destinations any quicker than I had with my previous FLD 120, which was equipped with a Detroit Series 60 360 / 400 HP / 1450 FPT. For this reason, I took my truck to the Detroit distributor and had my engine's horsepower turned from 500 HP to 430 HP, which ended up increasing my fuel efficiency an additional 4/10ths of a mile per gallon.

I kept my 2001 Freightliner Century truck for 915,000 miles with minimal repairs. Those repairs included the replacement of one set of fuel injectors, at approximately 650,000 miles, and a camshaft at 725,000 miles. The camshaft was damaged, because my engine was equipped with a PAC-BRAKE that had a housing crack, allowing it to bounce around on top of my valve train and camshaft. When I replaced the camshaft, I also replaced the PAC-BRAKE with a Jacob's engine brake. Another thing I was surprised by, was that this truck had greaseless u-joints, along with greaseless slack adjusters. This last item, to my, and my main mechanic's astonishment, performed flawlessly for 915,000 miles without ever needing any grease.

The overall lifetime average for fuel mileage on my 2001 Freightliner Century was 7.2 mpg. This would have been a lot higher, except for the fact that I hauled a lot of chain link fence.

The next step into this series will be on the subject of my first Freightliner Cascadia.