|

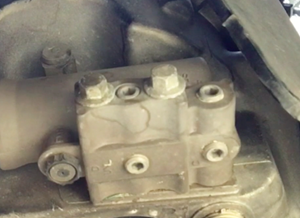

| Our old Air Governor |

The air dryer is one of those things nobody thinks about till it becomes a problem. Doing a simple service is somewhat easy on the Wabco/Meritor dryer. Now you may ask "Why does the air system have a dryer?" Well, I’ll tell you to the best of my abilities.

As air is compressed it becomes heated, just part of the compressing process. This compressed air will have moisture in it; no matter where you are there is some moisture in the air. As the compressed air leaves the compressor it starts to cool, when the air cools the moisture will begin to condense and fall out of the air. This cooling/condensing we hope happens in the dryer. If not, most systems have an air tank that is smaller than the rest and is the first one in line after the dryer; I call this the wet tank. Why? Because any moisture that gets past the dryer will usually fall out in this tank and it will gather the water, it could fill if the dryer isn't working and you don't drain it regularly. This could flood the air system with moisture and could freeze in cold weather, preventing some or all of the air supplied systems from working, including the brakes.

A truck has many air-supplied items, including but not to limited to, the brakes, the truck suspension, the seat, the cab suspension and some transmissions have air to shift them. Some may even remember air operated windshield wipers, thankfully those went away, they didn't work as well as electric ones do, in my opinion.

As you travel the roads, all these items are using compressed air to operate. The air compressor is driven by the engine and is regulated by a governor that will "turn" on and off the compressor. This is done internally in the compressor so there is nothing you can see working like the A/C compressor clutch.

The pressures are pre-set in the governor at the factory so there is nothing to be set by you when replacing one. The governor is one of the items that I change when servicing the air dryer.

In order to service the air dryer you need to completely drain the air system. This can be done two ways, pump the brakes until there is no air left, or open the drain valves at each tank until empty. I guess you could use a combination of both, pump the brakes down very low then open the drain valves. I like to remove the valves from each tank just to make sure all the moisture is drained.

Once the air system is completely empty we can begin working on the dryer. This dryer is especially easy, in my opinion, to service. The filter is a spin on and the governor has no airlines to it, everything is taken care of internally. I don't want to get into the deeper parts of the dryer unless there is a problem, kind of, like the engine. Then I would replace it with a remanufactured or a new one which ever is the better value.

Ok, we have all the air out of the system, gauges at zero, nothing when we step on the brake pedal, and nothing at any of the air tank valves. On a Cascadia with a DT12 transmission, there will be at least four valves. The wet tank, the transmission tank, and primary and secondary tanks, that's four, there may be others if additional air operated equipment has been installed on the truck. Easiest thing first, spin off the filter, it's right there on top of the dryer. I had to purchase a special filter wrench to get it loose, it's quite large and tight. Righty tightly, lefty loosey. Once the filter is loose, spin it off and discard. Take a clean rag and wipe off the inside of the dryer where the filter was, there may be some oil and/or water in there, that's normal. You will see the new filter came with an O-ring, with the old filter off you will see an O-ring on the threaded part of the dryer, remove and discard the old one, wipe off the threaded part.

Install the new O-ring in the same location as the old one was. I like to use some O-ring grease on the O-ring and on the seal of the filter where it contacts the dryer. You can get O-ring grease at any parts store, a very small tube will suffice. Now you can spin on the new filter, it needs to be as tight as you can get it by hand, you don't need to use the wrench on it.

Now to change the governor. On this dryer the governor is mounted to the dryer, one gasket and two bolts, these will come in the new governor kit. I used a 3/8 ratchet and a 10mm deep socket, the bolts are easy to remove and the old governor will fall off. Remove the old gasket (if it didn't come off with the governor) and make sure the mounting surface is clean with no gasket residue. Using new bolts through the proper holes in the governor, place the gasket over the bolts, making sure all the holes line up, gasket with the governor. Install the new governor in the same orientation as the old one, making sure the gasket is in its proper place. Do not use any gasket sealer, this may plug or restrict one of the ports between the dryer and the governor that could cause the air system to malfunction.

I'm sure there is a torque spec for the governor bolts but i didn't look it up, just make sure they are tight, and remember they are threaded into aluminum so be careful to not strip or pull the threads. Now is when I like to start the truck, the compressor should be making air and with the valves out of the tanks, the new air will purge anything that shouldn't be in the tanks out. After a minute or two shut off the engine and reinstall the valves in the tanks, make sure they are closed. Once that is done restart the engine and listen for leaks. Once the air dryer "pops", that means the governor has shut off the compressor. Check that the pressure is the same on both primary and secondary gauges and that they are where they should be, Cascadia DT12, about 145 psi.

Next, pump down the air with the foot brake slowly until the compressor comes back on, somewhere around 120 psi. You should be able to hear the different sound of the engine, compressor on or off. The sound difference will be near the intake of the trucks engine. If you're happy with your numbers, shut off the engine and check for leaks everywhere you had something loose or off. If there are no leaks you're good to go. I do like to keep the old governor in the toolbox in case the one on the truck fails, but only if there wasn't an issue with that one. Hood down and latched, ready to hit the road. With this brand of dryer one could change the governor on the side of the road if necessary in about five minutes, there would be some shortcuts beside the road but you could get yourself out of a jamb if you carried a spare air governor.

The one time I wasn't carrying a spare governor was early in my driving career and was woken up by a low-pressure alarm at three in the morning. Three hours later the truck was fixed by a road service and we could go back to sleep, ha ha, I carry a spare now. Be safe out there.